Automation has become a defining factor in modern manufacturing, driven by the need for flexibility, speed, and precision. As production lines evolve toward high-mix and low-volume manufacturing, robotic systems must adapt quickly to different tasks. This is where the universal robot gripper plays a critical role, especially when combined with Automated Gripper change applications. Together, these technologies enable robots to perform multiple operations efficiently without manual intervention.

From assembly and material handling to packaging and inspection, universal grippers and automated tool-changing systems are transforming how industries approach robotic automation.

Table of Contents

ToggleUnderstanding the Universal Robot Gripper

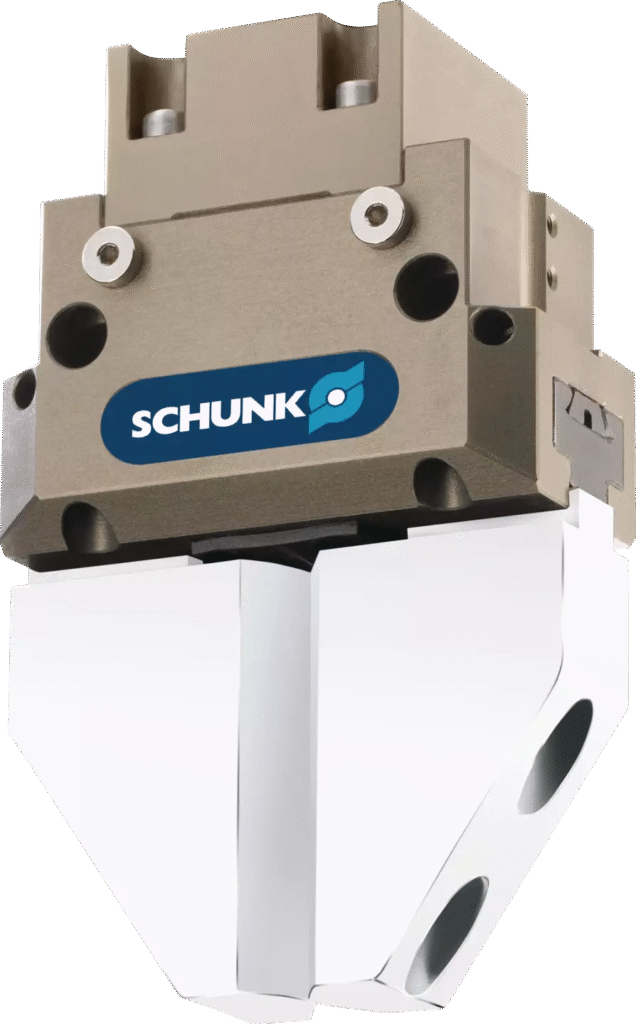

A universal robot gripper is a versatile end-of-arm tool designed to handle a wide variety of parts with different shapes, sizes, and materials. Unlike task-specific grippers, universal grippers are engineered to adapt to multiple applications, reducing the need for frequent tool replacements.

These grippers typically use pneumatic, electric, or hybrid mechanisms to provide controlled gripping force and repeatable performance. Their adaptability makes them ideal for dynamic production environments where flexibility is essential.

What Is Automated Gripper Change?

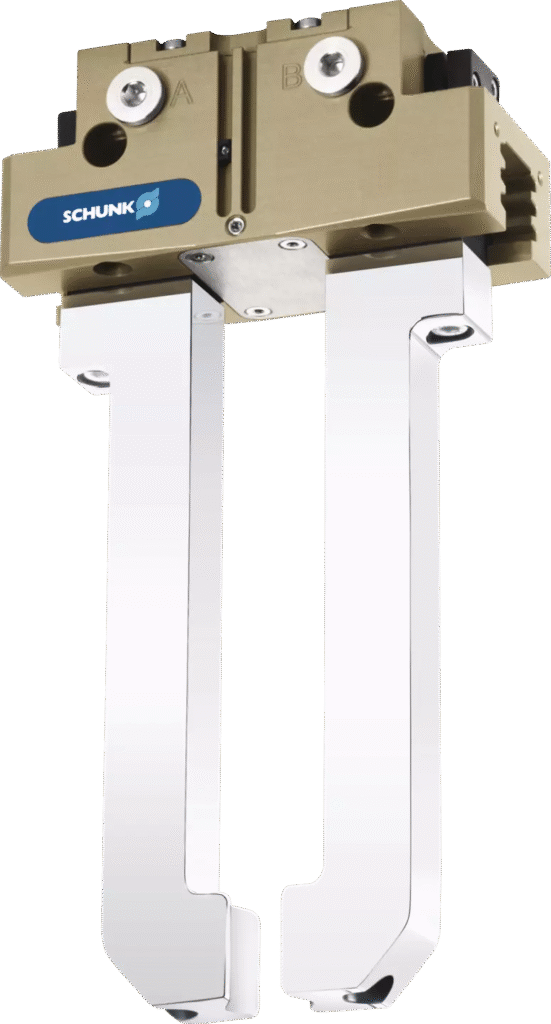

Automated Gripper change refers to a system that allows robots to automatically switch between different grippers or tools during operation. Instead of stopping production for manual tool changes, the robot docks the current gripper and picks up another one as required.

This automated process significantly reduces downtime and enables robots to perform multiple tasks within a single cycle. When paired with a universal robot gripper, automated gripper changes systems maximize operational efficiency and flexibility.

Why Universal Robot Grippers Are Ideal for Automated Tool Changes

The design of a universal robot gripper makes it especially suitable for automated tool-changing systems. These grippers are compact, lightweight, and compatible with standardized interfaces, allowing seamless integration with robotic arms and tool changers.

Because universal grippers can handle a wide range of components, fewer tool changes are needed. When combined with Automated Gripper change, robots can adapt to varying tasks without compromising speed or accuracy.

Enhancing Flexibility in High-Mix Production

Manufacturers increasingly deal with frequent product changes and customized orders. Traditional robotic setups struggle to keep pace with these demands. A universal robot gripper addresses this challenge by enabling robots to grip different parts without reconfiguration.

When automated tool changes are required, Automated Gripper change systems allow robots to switch grippers instantly. This combination supports flexible manufacturing cells capable of handling multiple product variants efficiently.

Improving Productivity and Reducing Downtime

Manual gripper changes can lead to significant production delays and increased labor costs. Automated solutions eliminate these inefficiencies. With Automated Gripper change, robots can transition between tasks without stopping the production line.

The use of a universal robot gripper further reduces downtime by minimizing the number of tool changes required. This results in faster cycle times, improved throughput, and better utilization of robotic assets.

Supporting Precision and Consistency

Consistency is crucial in automated manufacturing. A universal robot gripper provides controlled and repeatable gripping force, ensuring parts are handled accurately every time. This precision is essential for applications such as assembly, inspection, and machine tending.

When integrated with Automated Gripper change, the system maintains consistent performance across different tools and tasks, reducing errors and improving overall product quality.

Read more: Grip Tool Holders Explained: Choosing the Right Tool Holders for Precision Machining

Applications Across Multiple Industries

The combination of universal grippers and automated tool-changing systems is widely used across industries. In automotive manufacturing, robots switch between gripping body panels, fasteners, and assemblies. In electronics, delicate components are handled with precision and care.

Packaging and logistics operations benefit from the adaptability of a universal robot gripper, while Automated Gripper change enables quick transitions between packaging formats. These technologies are also increasingly used in metalworking, plastics, and consumer goods manufacturing.

Integration with Collaborative Robots

Collaborative robots, or cobots, are designed to work alongside humans and often require high levels of flexibility. A universal robot gripper complements cobots by enabling them to perform multiple tasks safely and efficiently.

With Automated Gripper change, cobots can adapt to different operations without manual setup, making them ideal for small and medium-sized enterprises looking to automate without complex infrastructure.

Role in Smart Manufacturing and Industry 4.0

Smart factories rely on interconnected systems, real-time data, and automated decision-making. Automated Gripper change systems support this vision by enabling autonomous tool selection based on production requirements.

A universal robot gripper contributes to this ecosystem by offering predictable and reliable performance. Together, they help create intelligent robotic systems capable of adapting to changing production demands with minimal human intervention.

Safety and Operational Efficiency

Safety is a critical consideration in automated environments. Automated gripper changes reduce human involvement in tool handling, minimizing the risk of injury. A universal robot gripper further enhances safety by providing stable and secure gripping during operation.

These systems also simplify maintenance and training, as operators manage fewer specialized tools and processes.

Choosing the Right Gripper and Tool-Changing System

Selecting the right universal robot gripper and Automated Gripper change solution depends on factors such as payload, part geometry, cycle time, and application complexity. Compatibility with robotic arms and control systems is also essential.

Partnering with experienced automation solution providers ensures that grippers and tool changers are properly integrated and optimized for long-term performance.

Conclusion

The increasing demand for flexible, efficient, and intelligent automation has made the universal robot gripper a key component in modern robotic systems. When combined with Automated Gripper change, it enables robots to perform multiple tasks seamlessly, reducing downtime and increasing productivity. This powerful combination supports high-mix production, improves consistency, and aligns perfectly with Industry 4.0 objectives.

For manufacturers seeking advanced robotic gripping and automated tool-changing solutions, trusted technology leaders like Schunk offer innovative systems that help businesses achieve reliable, future-ready automation.