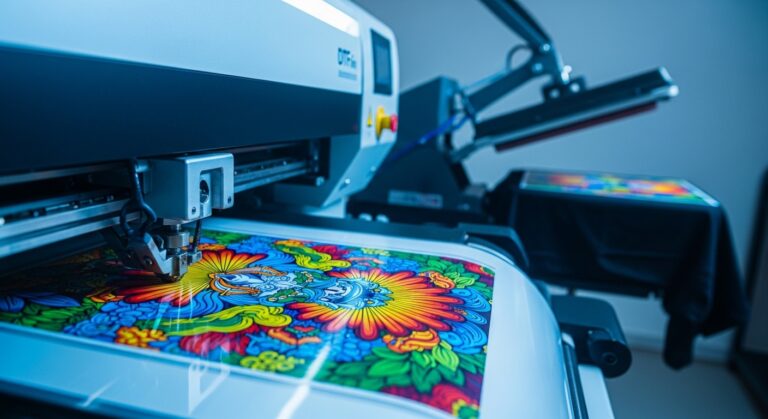

The custom apparel industry has seen massive shifts over the last decade. From the labor-intensive days of traditional screen printing to the rise of Direct-to-Garment (DTG) and Sublimation, technology has always pushed the boundaries of what is possible. However, no technology has disrupted the market quite like Direct-to-Film (DTF) printing.

Whether you are an entrepreneur looking to start a clothing brand or a seasoned print shop owner looking to optimize your workflow, understanding the nuances of DTF is essential. At Sparky Post, This guide covers everything from the basic mechanics to advanced troubleshooting and business scaling.

Table of Contents

Toggle1. What Exactly is DTF Printing?

At its core, Direct-to-Film (DTF) is a printing process that involves printing a digital design onto a specialized PET (Polyethylene Terephthalate) film. Unlike DTG, where the ink is jetted directly onto the fabric, DTF uses a “transfer” method.

The process involves four primary components:

- Pigment Inks: Specialized CMYK and White inks.

- PET Film: A plastic-like film with a coating that holds the ink.

- Hot-Melt Adhesive Powder: A granular glue that bonds the ink to the fabric.

- Heat Press: The final engine that transfers the cured design onto the garment.

The Science of the Bond

The reason DTF is so durable lies in the chemistry of the adhesive. When the hot-melt powder (usually a TPU-based material) is heated, it undergoes a phase change from a solid grain to a viscous liquid. This liquid seeps into the fibers of the fabric. Once it cools and solidifies, it creates a mechanical bond that is incredibly resistant to washing, stretching, and friction.

2. The Step-by-Step DTF Workflow

To achieve a retail-quality finish, the workflow must be precise. Any shortcut in these steps can lead to peeling or color fading.

Step 1: Design and RIP Software

Everything starts with a high-resolution digital file. In DTF, you cannot simply “hit print” from a standard photo viewer. You need RIP (Raster Image Processor) Software. This software tells the printer exactly how much white ink to lay down as an “under-base” so that the colors pop on dark fabrics.

Step 2: Printing onto the Film

The printer first lays down the CMYK colors. Immediately after, it prints a thick layer of white ink over the top of the colors. This white layer acts as the “bridge” between the color and the adhesive.

Step 3: Application of the Adhesive Powder

While the white ink is still wet, the film passes through a powdering station. The adhesive powder sticks only to the wet ink. Any excess powder is shaken off (manually or by an automated shaker machine) to ensure the non-printed areas remain clean.

Step 4: Curing the Film

The powdered film is placed in a curing oven or under a heat press at a height of about 2–3 inches. The goal is to melt the powder until it looks “orange-peel” textured and shiny. This usually happens at temperatures between 285°F to 325°F.

Step 5: The Heat Press Transfer

The cured film is placed on the garment and pressed. For most cotton and polyester blends, a firm pressure for 10–15 seconds is ideal.

Step 6: The Peel

Depending on the type of film used, you will either perform a Hot Peel (removing the film immediately) or a Cold Peel (letting the garment cool completely). Cold peels generally offer a more matte, retail-ready finish.

3. DTF vs. The Competition: A Comparison

To understand why DTF is winning, we have to compare it to the “Big Three” of the industry.

DTF vs. Screen Printing

Screen printing is the gold standard for bulk orders (500+ shirts). However, the setup time is grueling—burning screens, mixing inks, and cleaning up chemicals. DTF requires zero setup. You can print one shirt or a hundred with the same amount of effort. Furthermore, DTF handles gradients and photorealistic details that screen printing struggles to replicate without advanced halftones.

DTF vs. DTG (Direct-to-Garment)

DTG was once the king of “Print on Demand.” However, DTG is notoriously finicky. It requires “pre-treatment” (a liquid primer) on every shirt, which can leave stains or “hoop marks.” DTF requires no pre-treatment. Additionally, DTG only works well on 100% cotton, whereas DTF works on almost everything.

DTF vs. Sublimation

Sublimation is fantastic for polyester, but it is invisible on cotton and dark colors. DTF solves this by providing a white ink base, allowing you to put bright, vibrant designs on black hoodies, navy blue polos, and even leather jackets.

4. Why Fabric Versatility Matters

One of the biggest selling points for your business is the ability to say “Yes” to every customer.

- Cotton: The classic choice. DTF feels soft and breathable on cotton.

- Polyester & Sportswear: DTF is flexible. It stretches with the fabric, making it perfect for gym wear and jerseys.

- Nylon & Raincoats: Traditionally hard to print on, DTF adhesive bonds well to synthetic fibers.

- Canvas & Bags: DTF is great for tote bags and heavy-duty canvas.

- Leather: You can customize leather jackets and patches using low-heat DTF settings.

5. Quality Control: The “Feel” and the “Wash”

A common concern with transfer printing is the “plastic feel” (the hand-feel). High-quality DTF prints are surprisingly thin. If you use the right amount of powder and a high-quality PET film, the print will feel like a part of the fabric rather than a sticker sitting on top of it.

Durability Standards

A properly executed DTF print should last for 50+ washes without significant cracking or fading. This puts it on par with high-end screen printing. To maintain this quality, it is vital to source your materials correctly. For instance, using premium transfers from Wise DTF Prints ensures that the ink-to-powder ratio is professionally balanced, giving your customers a product that looks new even after months of wear.

6. Common DTF Pitfalls and How to Avoid Them

Even with the best technology, things can go wrong. Here are the most common issues:

- Oily Residue: If you see “sweat” or oil on your prints, it’s usually due to incomplete curing or poor-quality ink.

- White Ink Clogging: White DTF ink is heavy with Titanium Dioxide. If your printer sits idle, the ink settles and clogs the heads. Constant agitation or a circulation system is a must.

- Cracking After Wash: This happens if the heat press pressure was too light or the temperature was too low. The adhesive didn’t fully sink into the fibers.

- Poor Color Matching: Ensure your RIP software is using the correct ICC profiles for your specific ink and film combination.

7. The Business ROI of DTF Printing

From a business perspective, DTF is incredibly lucrative. The cost per print is significantly lower than DTG.

Cost Breakdown Example:

- A standard 10×10 inch full-color print costs roughly $0.75 to $1.25 in materials (ink, film, powder).

- A blank high-quality t-shirt costs $3.00 to $5.00.

- Total cost: ~$6.00.

- Retail price: $20.00 to $25.00.

The profit margins are excellent, especially for small to medium runs. Furthermore, because you can print the films in advance and store them, you can fulfill orders in seconds. This makes “live printing” at events or rapid-fire Etsy shipping possible.

8. Sustainability in DTF

In 2026, customers care about the environment. DTF is generally more eco-friendly than screen printing because it produces less water waste. There are no screens to wash out with chemicals. Additionally, many PET films are now being developed with recyclable coatings, and water-based pigment inks are the standard in the industry.

9. Future Trends: What’s Next for DTF?

We are already seeing the next evolution of DTF:

- Fluorescent DTF: Neon inks that glow under UV light.

- Gold & Silver Foil DTF: Adding metallic finishes without the hassle of traditional foil weeding.

- High-Speed Shakers: Automated systems that can process 50 meters of film per hour.

10. Conclusion: Why Wise DTF Prints?

The barrier to entry for DTF is low, but the barrier to quality is high. Anyone can buy a cheap printer, but consistent, vibrant, and durable transfers require professional-grade equipment and environmental control.

If you want to skip the headache of maintenance and technical troubleshooting, outsourcing your transfers to experts is the smartest move. By choosing Wise DTF Prints, you gain access to the highest industry standards, allowing you to focus on what you do best: designing and selling.

DTF isn’t just a trend—it’s the new standard for the apparel world. Embrace the film, and watch your creative possibilities expand.