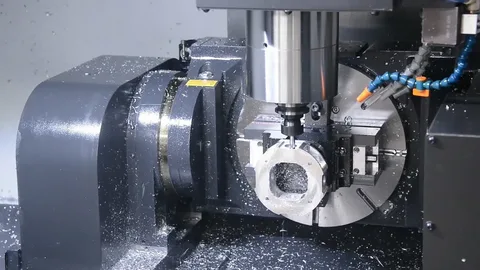

In today’s rapidly evolving manufacturing landscape, efficiency, precision, and adaptability are more critical than ever. One technology that has revolutionized modern factories is CNC machining for automation. By integrating computer-controlled processes with automated machinery, manufacturers can achieve higher productivity, superior quality, and cost savings. This article explores the top benefits of CNC machining for automation and how it is shaping the factories of the future.

Table of Contents

ToggleEnhanced Precision and Consistency

CNC machining for automation ensures that every part produced meets exact specifications. Unlike manual machining, which is prone to human error, CNC machines follow programmed instructions with extreme accuracy. This precision is particularly crucial in industries like aerospace, automotive, and medical equipment, where even minor deviations can compromise safety or performance. Automated CNC systems maintain consistency across thousands of units, guaranteeing uniformity in each product batch.

Moreover, CNC automation allows manufacturers to replicate complex designs that would be difficult or impossible with traditional methods. Once a program is set, machines can produce identical components repeatedly without the need for constant human oversight. This not only reduces errors but also enhances the overall reliability of the production process. Businesses benefit from fewer defects, lower waste, and higher customer satisfaction, all of which are vital in competitive markets.

Increased Production Efficiency

One of the most significant advantages of CNC machining for automation is its ability to dramatically improve production efficiency. Automated systems operate continuously, with minimal downtime, enabling factories to maintain high output levels. Unlike manual machining, which requires frequent breaks and human supervision, CNC machines can run around the clock, significantly reducing production lead times.

Additionally, CNC automation streamlines workflows by integrating multiple processes into a single machine or production line. Operations such as cutting, drilling, and milling can be performed consecutively without transferring parts between different stations. This integrated approach minimizes handling time, accelerates production cycles, and allows factories to meet growing market demands more effectively.

Cost Savings in the Long Run

Although the initial investment in CNC machining for automation can be substantial, the long-term cost benefits are undeniable. Automated systems reduce the reliance on manual labor, cutting labor costs and minimizing the risk of human error, which often leads to expensive rework or material waste. Factories that adopt CNC automation can optimize resource utilization and achieve higher efficiency with fewer operational expenses.

Furthermore, CNC machines require less downtime for maintenance compared to traditional equipment. Predictive maintenance tools can monitor machine health, allowing operators to address potential issues before they escalate into costly breakdowns. Over time, these factors translate into significant savings, making CNC machining for automation a financially sound investment for manufacturers aiming to improve profitability while maintaining product quality.

Flexibility and Adaptability in Production

CNC machining for automation offers unmatched flexibility, enabling factories to adapt quickly to changing production requirements. Programmed machines can switch between tasks or adjust specifications without the need for extensive retooling. This is particularly valuable in industries with high product variety or frequent design updates, where traditional machining methods would struggle to keep pace.

The adaptability of CNC systems also allows manufacturers to experiment with new materials or designs without significant disruptions. Companies can prototype quickly, test new concepts, and transition seamlessly to full-scale production. This agility not only supports innovation but also provides a competitive edge in markets where speed and responsiveness are crucial for success.

Improved Safety and Reduced Workplace Risks

Another key benefit of CNC machining for automation is the enhancement of workplace safety. Automated machines reduce the need for human operators to handle sharp tools or heavy machinery, significantly lowering the risk of accidents. Employees can focus on monitoring and programming machines rather than performing hazardous tasks, creating a safer work environment.

In addition, CNC systems often include safety features such as emergency stops, protective enclosures, and real-time monitoring to prevent accidents. By minimizing human exposure to potential hazards, factories can comply with occupational safety regulations while maintaining high production standards. Ultimately, automation through CNC machining protects workers, reduces liability, and fosters a culture of safety within modern manufacturing facilities.

Conclusion

CNC machining for automation is transforming modern factories by enhancing precision, efficiency, cost-effectiveness, flexibility, and safety. Its integration into manufacturing processes allows businesses to stay competitive, meet high-quality standards, and respond quickly to market demands. From improving product consistency to reducing labor costs and workplace risks, the benefits of CNC automation are far-reaching.

As industries continue to evolve, the adoption of CNC machining for automation will be essential for factories aiming to achieve sustainable growth and operational excellence. By embracing this technology, manufacturers can not only streamline production but also secure their position at the forefront of innovation in the modern industrial landscape.

CNC machining for automation