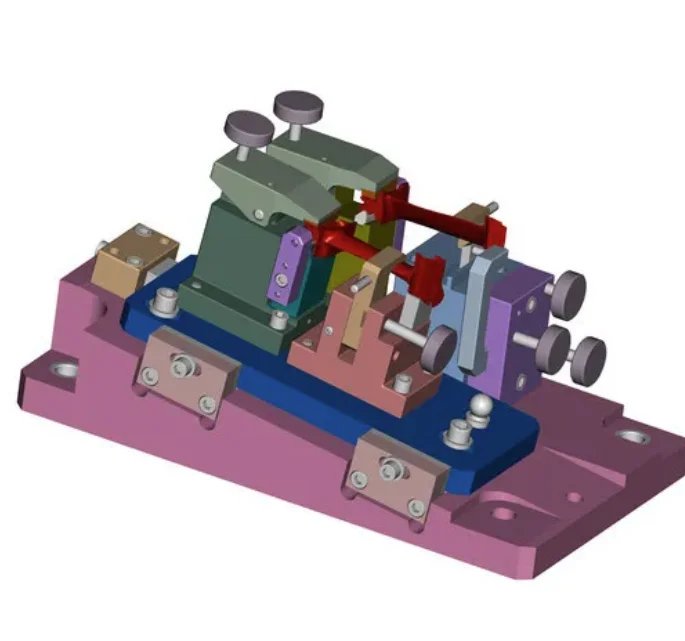

High-tolerance machining depends on control, repeatability, and process discipline. Every micron removed from a workpiece must follow a predictable path, and even minor instability can lead to rejected parts. In this environment, jigs and fixtures form the physical backbone of CNC accuracy by locking parts into precise positions and maintaining consistency throughout the machining cycle. Without engineered workholding, machine capability alone cannot guarantee tight tolerances.

As CNC components become more complex and tolerance limits continue to shrink, manufacturers must rely on dedicated jig and fixture design devices rather than general clamping solutions. Proper workholding reduces dimensional variation, stabilizes cutting conditions, and allows machining processes to scale without sacrificing quality. High-tolerance production is only sustainable when jigs and fixtures are designed as part of the machining strategy, not as an afterthought.

Table of Contents

ToggleThe Foundation of Dimensional Accuracy

Stable Workpiece Positioning Under Load

During machining, cutting forces act in multiple directions and can easily shift an unsupported part. Jigs and fixtures tooling counter these forces by providing rigid support at carefully selected contact points. This stability ensures that the workpiece remains fixed relative to the machine coordinate system, protecting dimensional accuracy and preserving feature alignment from start to finish.

Consistent Datum Control Across Cycles

High-tolerance parts require precise datum control to maintain relationships between features. Well-designed fixtures establish fixed reference points that are repeated every time a part is loaded. This repeatability eliminates cumulative error, supports multi-operation machining, and ensures that critical dimensions remain within specification throughout production.

Reducing Variation in CNC Machining

Eliminating Operator-Dependent Error

Manual setups introduce variability that precision machining cannot tolerate. Jigs and fixtures remove guesswork by guiding operators to place parts in exact positions every time. This consistency allows multiple operators and shifts to produce identical results, strengthening quality control and reducing dependency on individual experience.

Faster Setup Without Loss of Precision

High-tolerance machining often involves frequent changeovers. Purpose-built fixtures reduce setup time by enabling fast and repeatable loading while maintaining positional accuracy. Shorter setups increase spindle utilization and throughput while preserving strict tolerance control.

Fixture Design for Complex CNC Parts

Supporting Thin and Sensitive Features

Many precision components include thin walls, fine details, or unsupported areas that are prone to deformation. Advanced jig and fixture design devices distribute clamping forces across structurally strong zones while avoiding stress on sensitive features. This approach preserves geometry during machining and prevents dimensional changes after unclamping.

Maintaining Tool Access and Chip Flow

Effective fixtures stabilize the workpiece without blocking tool paths or chip evacuation. Good design allows cutting tools to reach all required features and ensures chips exit the cutting area cleanly. This improves surface finish, reduces tool wear, and supports consistent machining quality.

Material and Structural Considerations

Rigidity for Long-Term Accuracy

Fixtures used in high-tolerance environments must resist wear, vibration, and deformation. Rigid construction ensures that locating features remain accurate over thousands of cycles. Durable jig and fixture design devices protect process capability and reduce the need for frequent recalibration or replacement.

Managing Thermal Effects

Temperature variation can affect both parts and fixtures. High-precision machining requires fixtures that minimize thermal expansion and maintain consistent clamping pressure. Proper material selection and structural design help preserve dimensional stability during long machining cycles or changing shop conditions.

Supporting Multi-Stage and Multi-Axis Machining

Consistent Geometry Across Operations

Complex parts often move between multiple machines and setups. Jigs and fixtures provide stable datums that carry geometry through every stage of production. This continuity prevents tolerance stack-up and ensures features align correctly during final assembly.

Enabling Advanced CNC Capabilities

Multi-axis machining demands secure and precise workholding. Fixtures designed for five-axis operations allow full tool access while maintaining rigid support. This capability expands machining possibilities and supports the production of complex, high-precision components.

Quality Control and Process Reliability

Lower Scrap and Rework Rates

High-tolerance parts offer little margin for error. Proper jigs and fixtures tooling reduce dimensional variation, lowering the risk of inspection failures. Consistent machining outcomes reduce rework, protect delivery schedules, and improve overall production efficiency.

Predictable and Repeatable Processes

Reliable workholding transforms machining into a controlled process rather than a corrective one. When fixtures manage part behavior, results become predictable and measurable. This stability supports statistical process control and long-term quality improvement.

Benefits of Precision Jigs and Fixtures

- Improved dimensional accuracy and repeatability

- Reduced setup time and operator variability

- Better surface finish and longer tool life

- Lower scrap, rework, and inspection failures

Essential Features of High-Tolerance Fixtures

- Accurate locating with stable datum references

- Balanced clamping that avoids part distortion

- Open access for tools and chip evacuation

- Durable construction for extended service life

Collaboration Between Design and Machining

Incorporating Shop-Floor Insight

Effective jig and fixture design devices reflect real machining conditions. Input from machinists helps designers understand cutting forces, handling challenges, and loading efficiency. This collaboration ensures fixtures perform reliably in production environments.

Continuous Improvement Through Experience

Each production cycle provides data that can refine future fixture designs. Incremental improvements enhance accuracy, usability, and durability, strengthening the overall machining process and supporting increasingly tight tolerances.

Conclusion

High-tolerance machining depends on more than advanced CNC equipment. Jigs and fixtures provide the physical control needed to achieve repeatable accuracy, stable setups, and predictable results. By investing in precision jig and fixture design devices, manufacturers reduce variation, protect critical tolerances, and build reliable CNC processes. In demanding machining environments, effective workholding is the foundation that makes precision manufacturing possible.